competencies

What does our range of services look like? Find out here!

We do not only have a strong and manpowered engineering (concept creation, construction, software development, commissioning, CE marking) but also two production halls of our own, in which a team of mechatronics, machinists and fitters turn what has been developed by engineering into reality.

Your idea is enough for us. From this, we formulate the task with you and develop the concept together. In addition to your wishes and ideas, legal requirements, in particular safety requirements, are also compiled and recorded in the specification sheet. The concrete implementation / fulfillment of this requirement is described in the specification and only then do we start with the construction of the machine. The more thoroughly this concept phase runs, the faster we will be at the end with the manufacture of the machine / system.

Formulation of the task; Definition of all requirements; Creation of specifications

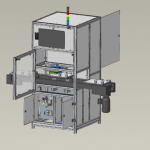

Within the scope of mechanical and electrical design, your machine / system is created virtually and on paper. The two trades work hand in hand. Especially in this phase of development, you are very close to us. Through 3D designs and simulations, you can experience how your machine / system grows bit by bit. It is good and important that you actively contribute your wishes and ideas. Changes up to the design release are much less time-consuming than changes to the built machine / system. However, the task of the designers does not end with the design approval, because they accompany the production of individual components and groups, the assembly and the commissioning. This is where the reduction of costs and time becomes particularly apparent, because we unite all trades in our company.

mechanical design:

3D – design / simulation, preparation of technical drawings and assembly instructions, support of manufacturing and commissioning (WSCAD, PTC Creo 2.0, AUTOCAD)

electrical / pneumatic / hydraulic design:

Preparation of E-plan / fluid-plan / pneumatic-plan / hydraulic-plan; ordering of components; supervision of assembly and commissioning; electrical tests (WSCAD)

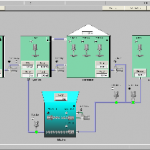

More than half of our employees are software developers. Therefore, we are highly capable in this area in particular. During programming, we do not only have in mind that the software is optimally structured and can be used intuitively, but also that it can be expanded or specified in the future without major effort. Especially with complex systems, a database can be useful, so that you can adapt your system to changing requirements through simple configuration and without software changes. Due to the ever shorter cycle times, robots are regularly used in our plants, so that we are also familiar with their programming. We can also look back on years of experience in the field of image processing.

PLC programming e.g. Siemens, Beckhoff, Moeller, ABB, Pansonic, Beck

Programming of process control and field bus systems e.g. PROFIBUS FMS + DP; PROFINET; EtherCAT; CAN

Databases and customised application programming e.g. C++, Delphi, DotNET, Visual Basic, Perl, PHP, MSAAccess

Programming visualisation / HMI e.g. TwinCAT, WinCC, PCS7, CITECT, InTouch, LabVIEW, DIAdem, VEE

Robot programming e.g. Kuka, ABB, Stäubli

Image Processing e.g. HALCON, Panasonic, Omron, Keyence

We have two assembly halls where a team of mechatronics, machinists, toolmakers and fitters turn what has been developed by engineering into reality.

With our own CNC milling machines, CNC lathes, welding workstations and other processing tools, we have an enormous range of capabilities. Customised components and assemblies are required, especially in special machine construction. We can manufacture them ourselves.

Follows soon…

Whether control panels, terminal boxes, serial cabinets or individual cabinets, we can assemble, wire and test switchgear of any kind.

Test reports; itemisation; VDE measurements

During assembly (electrical, mechanical, pneumatic, hydraulic), all components are combined with each other. This is usually done in our production halls by our fitters and mechatronics engineers. In addition, we carry out all assembly work on your premises in order to integrate the system at your site. In this regard, we are absolutely location-independent.

As far as possible, the complete assembly of the system takes place in our own production halls, so that the system is tested in its entirety before delivery. Verification and validation are particularly important for special solutions. Since the commissioning engineer is usually also the one who developed the software and we have developed and manufactured the system ourselves, commissioning can be optimised. Any weak points are detected and eliminated at an early stage. After delivery and successful release at your site, we are at your side during production, if necessary also in several shifts. Instruction and training are a standard part of our service.

From concept creation to final acceptance, we work consistently with Safe-Expert, a software for creating CE documentation. This is particularly helpful in the context of defining the legal requirements.

When creating the documentation, it is particularly important to us that it is complete and, above all, logically structured. For example, in the maintenance and spare parts plan you will also find the equipment designations and additional information on how special components should be replaced or maintained. We also give recommendations on which components you should keep in stock as spare parts. With the operating instructions, you will receive detailed “step-by-step instructions” such that you would be able to use the system even without instruction or training.

We will prepare the following documents:

Risk analysis, CE declaration, CE marking, type plate, labelling, operating instructions, operating manual, manufacturer documentation, plan and concept for maintenance and spare parts, technical documentation (design drawings, E-plan, pneumatic plan, hydraulic plan, software documentation)

Due to the large volume of documentation, we hand it over to you primarily in digital form, but of course also in paper form on request.

Particularly in the case of special solutions, support is absolutely essential even after successful final acceptance and expiry of the warranty period. We live this. Our on-call service is available to you 24/7 and, if necessary, we can also be on site. By means of remote maintenance, we can connect to your system in a few minutes and carry out targeted fault analysis and rectification. We will be happy to carry out regular maintenance and electrical check-ups for you.